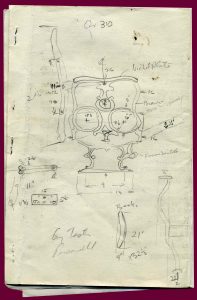

How our parts are made….

Our products are injection molded, using metal molds which are created in house. Today, our molds are engraved by computer….but back in the day, things were done differently.

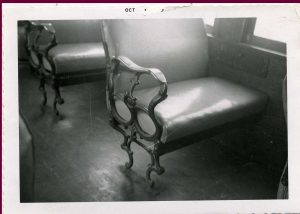

Here is how we made our parts pre-computer.

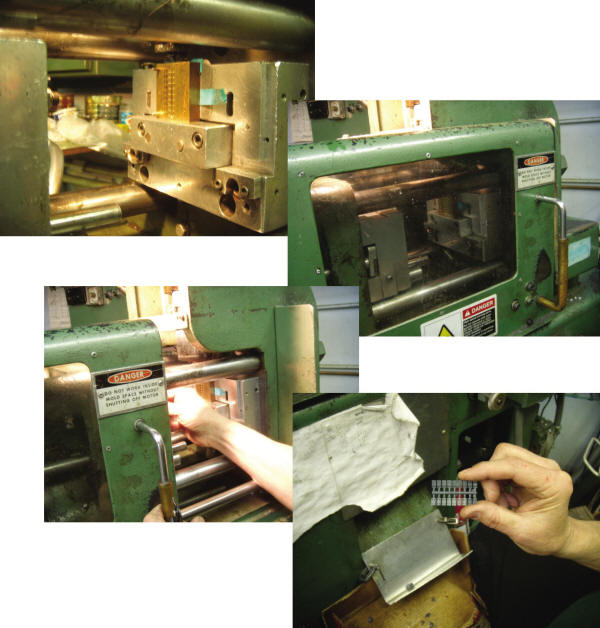

Here are our presses…

We use both automatic and hand operated injection molding machines to run the parts. Many of our older parts are done on the hand machines. Tie plates running on an automatic machine

One of our small injection machines